From Forbes by Kevin O’Marah …

Lego, the iconic and highly profitable Danish toymaker, is the latest business to be headed by an executive rising out of supply chain to the role of CEO. Business press covering the story largely focuses on the departure of current CEO and ex-McKinsey consultant Jorgen Vig Knudstorp, whose 12-year stint at the top has to be one of the best turnaround stories in corporate history. Bali Padda, who joined Lego in 2002, takes over and, according to reporting by the BBC, approaches the challenge with the following mindset:

“The world is being disrupted in many ways. How do we become a lot more agile to face the challenges that will come to us tomorrow?”

It’s hard to imagine a more supply chain-savvy CEO quote than that.

Believe in the Brick

Knudstorp’s brilliant performance as CEO includes a five-fold increase in revenue and a shift from losses of $1 million per day in 2004 to a 17% net profit in 2015. Much of this is of course due to smart investments in innovation and brand tie-ins that refreshed the product; however, such growth initiatives would have crashed and burned without an accompanying transformation in supply chain.

Five years later, Lego’s customers rated it “best in class”, with a service KPI of 96% on a two-hour window. Cost structures were converted to 85% variable and overall savings totaled 30% against a baseline set in 2005.

From a manufacturing standpoint, Lego’s leadership includes being well ahead of the curve on local-for-local supply chains, with plants in Mexico serving the American market, in the Czech Republic, Hungary and Denmark serving EMEA and, most recently in Jiaxing China serving Asia. We spoke to Mr Padda in early 2013 as part of our research on manufacturing footprints. The conclusions we drew at the time say a lot about how smart he is:

“…what has been successful at Lego is maintaining proximity and therefore short order cycle times for customers in each market. The company also uses a platform strategy with its product and manufacturing process design to protect IP and assure quality while still providing customer-specific localizations…”

What’s more, Lego’s investments in manufacturing automation and flexible production have been leading the industry in plastic injection molding techniques. Plus, postponement tactics that save final application of images onto figures allow for maximum item variety with minimal inventory risk.

It’s perhaps poetic that one of the great innovators in platforming strategy is the very company we so often use to explain the concept. The Lego brick, after all, is our favorite analogy for the product and process engineering approach that allows BMW and Mondelēz to offer lots of end-product selections to customers with minimal finished goods inventory.

Why this Matters

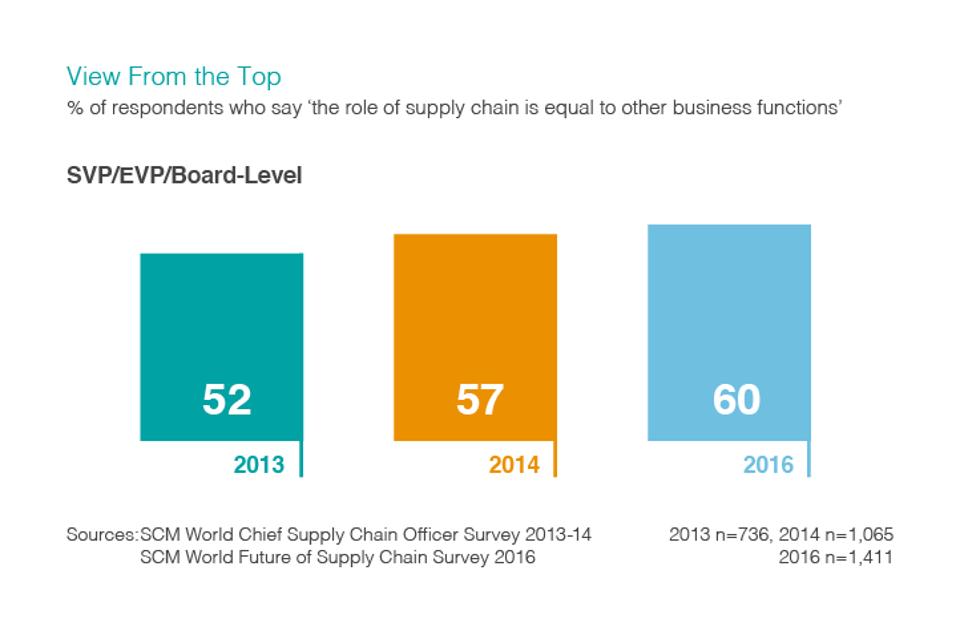

Business leadership is ultimately about profits, and the steadily rising profile of supply chain management as an equal partner to marketing, R&D and sales in delivering those profits has opened a new path to the top. Our recent Future of Supply Chain survey data shows continued gains in the stature of supply chain among C-suite executives.

For supply chain leaders, the advice is simple: stay true to your roots, but speak up about how your area of responsibility creates shareholder value. Looking ahead, digitization is enormously disruptive to traditional concepts of how money is made. Asset-light, intellectual property-intensive businesses like Apple, Microsoft and Disney depend on supply chain management less because it helps make stuff cheaper and more because it allows the business to monetize IP.

For a final proof point, consider that Knudstorp’s post-CEO plans don’t focus on retiring to the beach somewhere, but instead to chair a new entity called the Lego Brand Group. This new group’s mission is to focus on “new and exciting opportunities for the brand”.

With Mr Padda guiding the flagship, the possibilities are endless.

Become a LEGO Serious Play facilitator - check one of the upcoming training events!

Become a LEGO Serious Play facilitator - check one of the upcoming training events!